PRODUCT

PRODUCT

Home > PRODUCT > U.T.M

Home > PRODUCT > U.T.M

The QM100TC is a chamber-type universal material tester for measuring changes in material properties due to cold/heat characteristics

by performing tensile, compression, and bending tests under various environmental conditions from cryogenic to high temperature.

Liquid nitrogen and refrigerator can be selected depending on the characteristics of the low temperature section, and the wide

and abundant internal space and detachable head cover allow quick and convenient replacement of grip and fix test pieces.

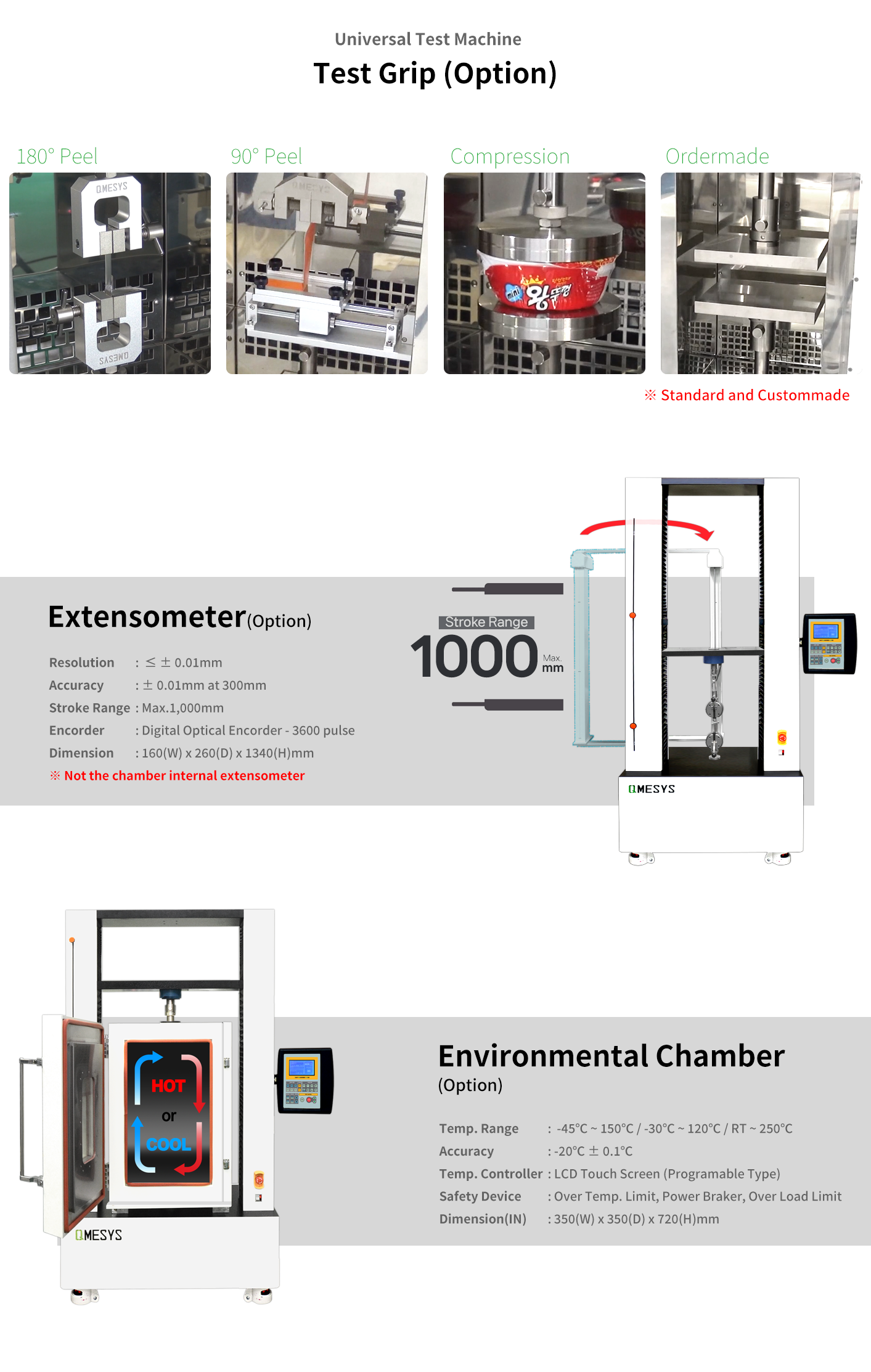

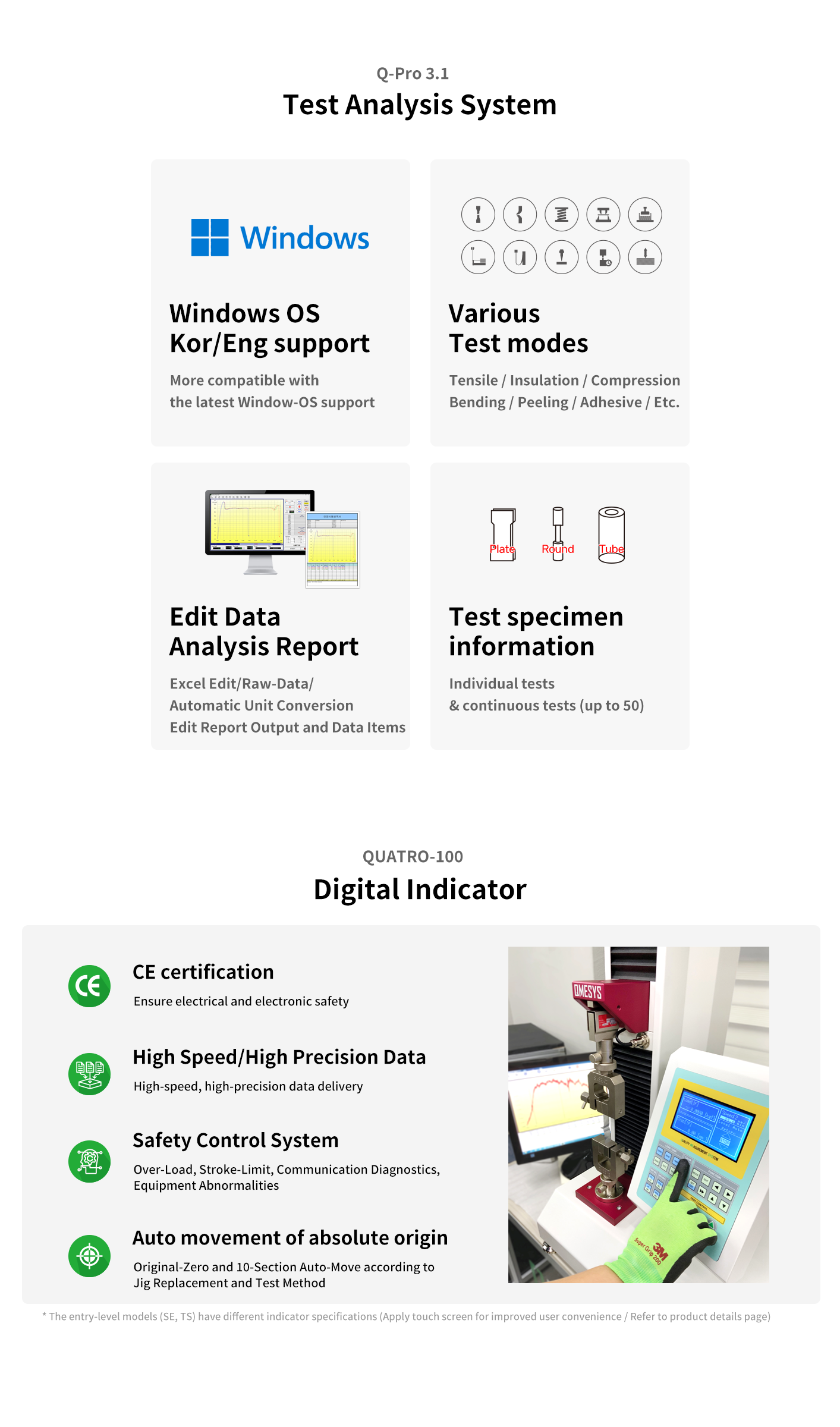

● Select different temp. ranges depending on the material● Easy-to-remove and convenient slide head cover for grip● Selection of cooling method according to the conditions of the low temperature test (Refrigerator & Liquefied Nitrogen method)● Separation standalone sliding table● Application of Load Cell Deformation Prevention Guard System under Thermal Characteristics Conditions● Chamber-only wide UTM (Axis-to-Axis Max.650mm)(tension, tear, peeling, compression, bending, hardness, friction, repetition, maintenance, hardness test, etc.)● Convenient sample information input function (automatic cross-sectional operation, continuous test measurement, automatic unit conversion, etc.)● Various test speed settings (distance speed, load speed, multi-section speed, etc.)● Data editing functions (excel support, parameter editing, raw data numerical view, interval setting, etc.)● Real-time monitoring (communication, overload, safety, measurement)● Remote Control Diagnostics and Remote Training Support● Extensometer, strain gauge, and environmental chamber interlocking function

Specifications

| MODEL | QM100TC (범용) | QM100TC (고급) | QM100TC (상온) | ||

|---|---|---|---|---|---|

| Temp. Range | -30~120℃ | -45~150℃ | RT~250℃ | ||

| Temp. Controller | LCD Touch Screen (Programmable Type) | ||||

| Stroke Range | 700mm (Non Grip) | ||||

| Chamber Dimensions (In) | 350(W) x 350(D) x 720(H)mm | ||||

| Chamber Dimensions (Out) | 620(W) x 1300(D) x 1100(H)mm | ||||

| UTM 장착 시 | 1000(W) x 2200(D) x 2000(H)mm | ||||

닫기

Customer

Customer

TEL : 031-453-8555

info@qmesys.com

YouTube

YouTube